The adoption of Plastic Slip Sheets is not only a step towards reducing operational costs but also a stride towards embracing environmental responsibility. Our slip sheets are 100% recyclable, promoting a circular economy and reducing the carbon footprint of your operations. Moreover, their sleek design allows for easy handling and storage, making them a convenient choice for fast-paced logistic environments. One of the paramount advantages of employing slip sheets in your logistic operations is the significant weight reduction they offer compared to traditional pallets. Being substantially lighter, slip sheets lessen the overall weight of the shipment, which in turn, translates to lower transportation costs.

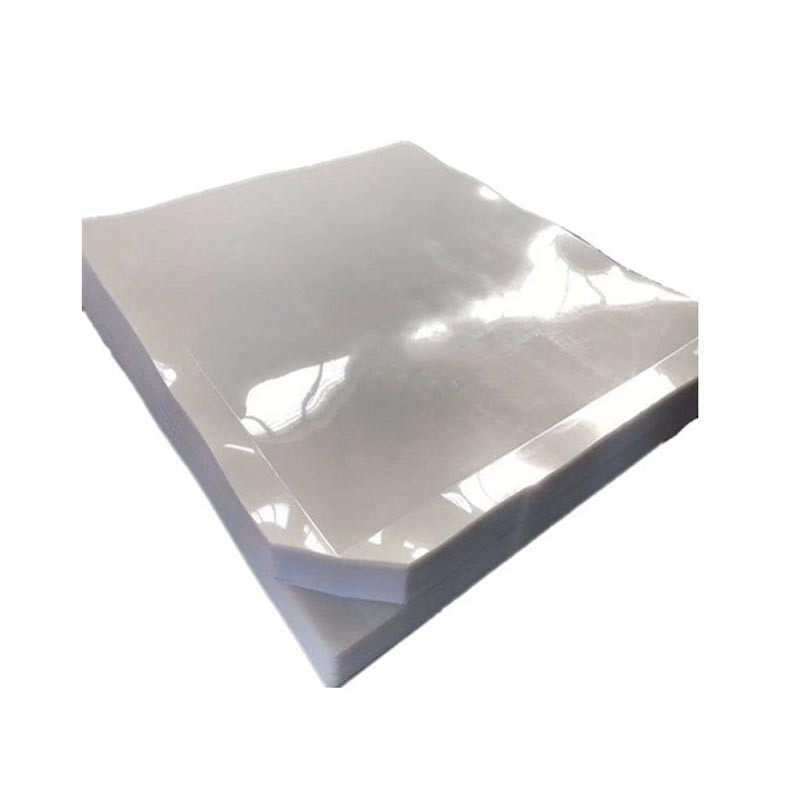

| 1 | Product name | slip sheet for transportation |

| 2 | Color | Kraft, Brown, Black |

| 3 | Usage | Warehouse & Transportation |

| 4 | Certification | SGS, ISO,etc. |

| 5 | Width of lip | Customizable |

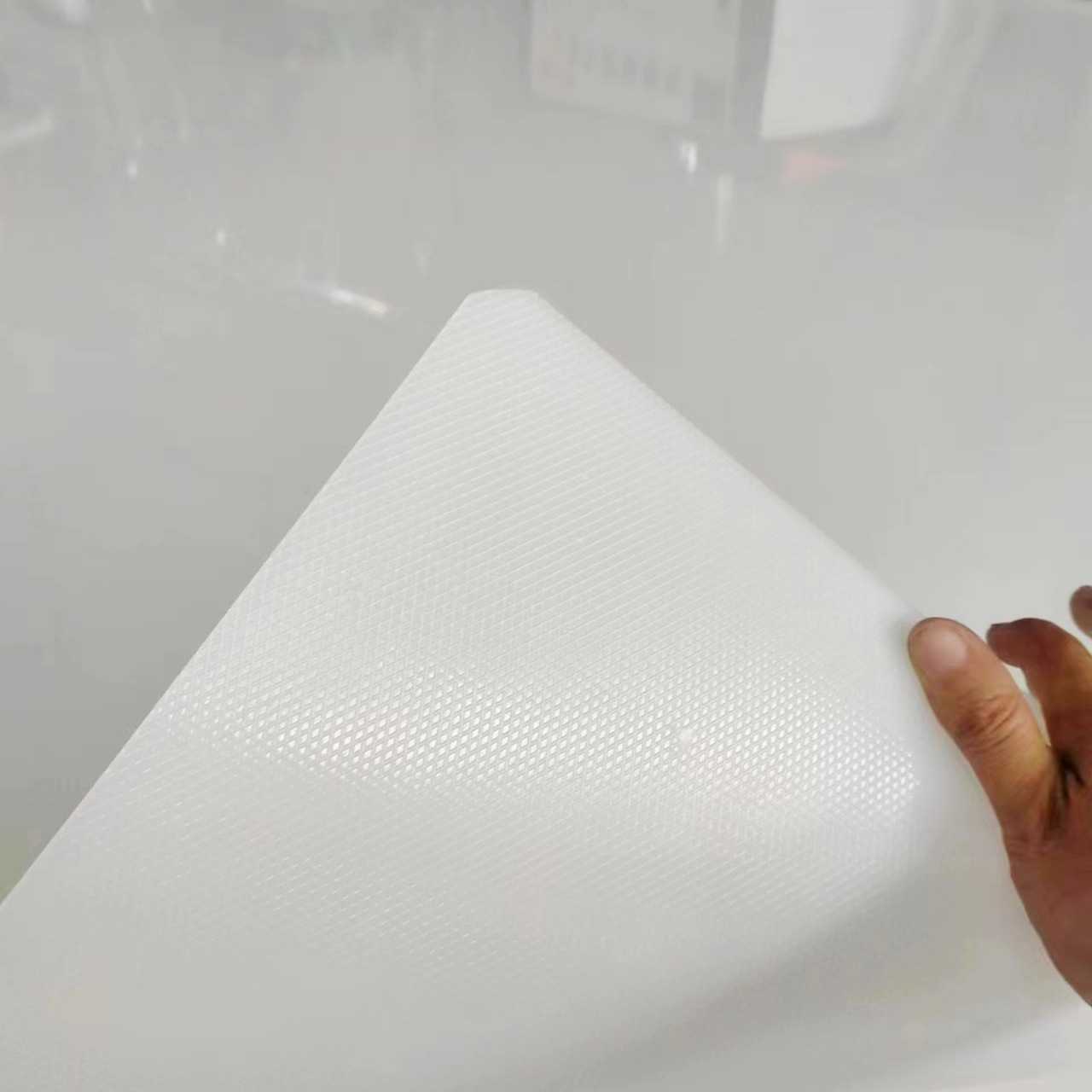

| 6 | Thickness | 0.6~2mm or customized |

| 7 | Loading Weight | 300kg-1800kg (for 3003500kg, please visit our plastic slip sheet) |

| 8 | Special handling | Available (moistureproof) |

| 9 | OEM Option | Yes |

| 10 | Drawing picture | Customer offer / our design |

| 11 | Types | One-tab slip sheet; two-tab slip sheet-opposite; two-tab slip sheet-adjacent; three-tab slip sheet; four-tab slip sheet. |

| 12 | Benefits | 1.Reduce the cost of material,freight,labour,repair,storage and disposal |

| 2.Environmentally-friendly, wood-free, hygienic and 100% recyclable | ||

| 3.Compatible with standard forklifts outfitted with push-pull attachments, rollerforks and morden conveyor systems | ||

| 4.Ideal for both domestic and international shippers | ||

| 13 | BTW | For the use of slip sheets all you need is a push/pull-device, which you can get from your nearest fork-lift truck supplier. The device is suitable for any standard fork-lift truck and the investment repays itself faster than you would think. You will get more free container space and save in handling and purchasing costs. |

Product Detail

|

Thickness (mm) |

g/㎡ |

loading weight(kgs) |

Friction coefficient |

Material |

|

0.6 |

580 |

0-600

|

0.45 |

Virgin HDPE |

|

0.8 |

750 |

700-900

|

0.45

|

Virgin HDPE

|

|

1.0 |

950 |

1000-1200

|

0.45

|

Virgin HDPE |

|

1.2 |

1150 |

1200-1500

|

0.45

|

Virgin HDPE |

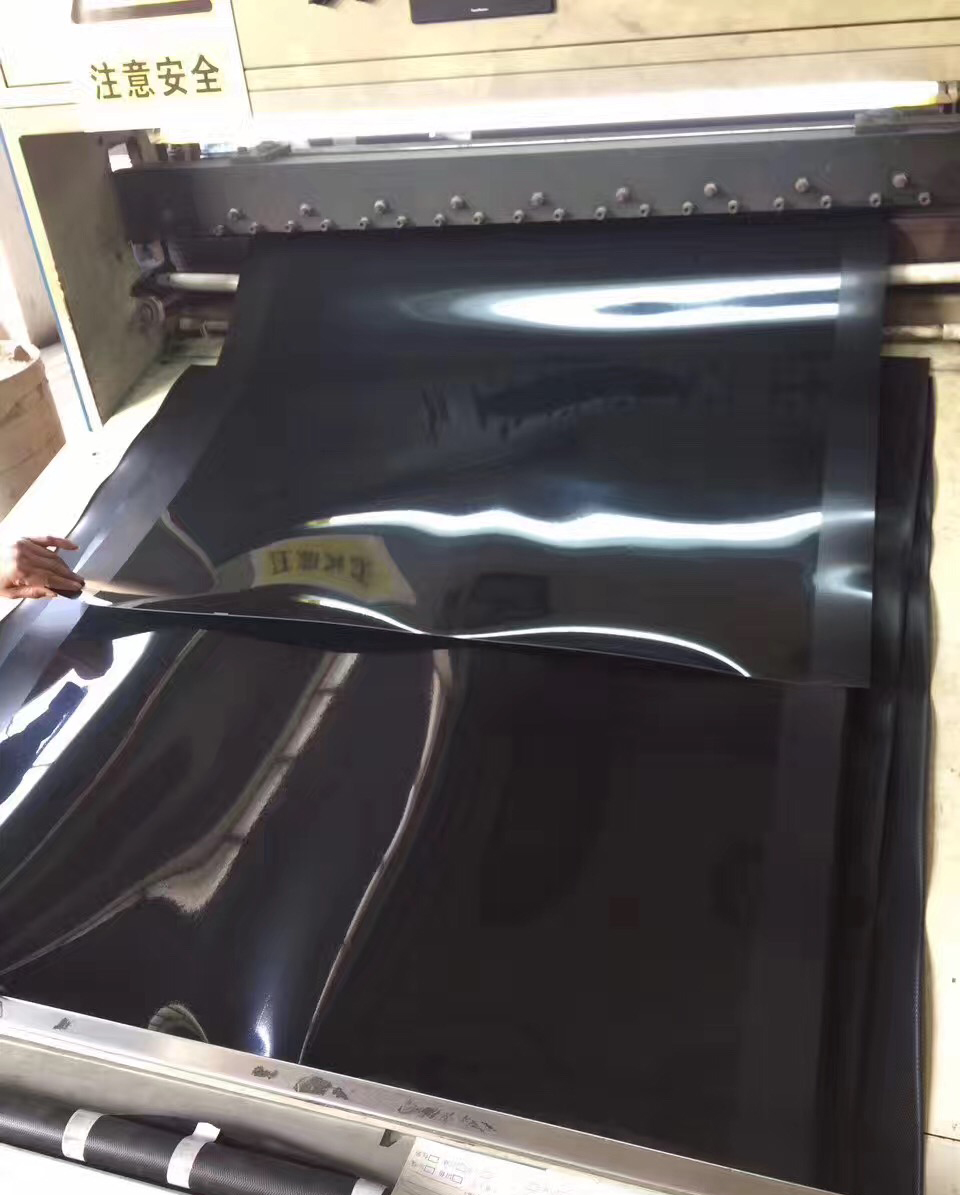

Production Line

Quality Control

Application

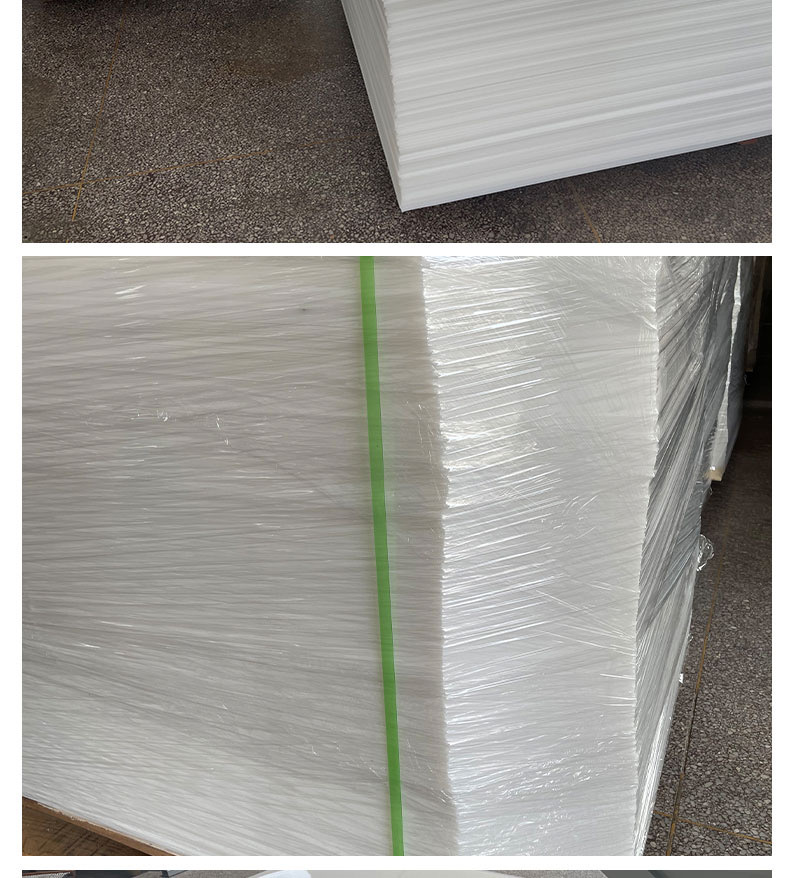

Packing