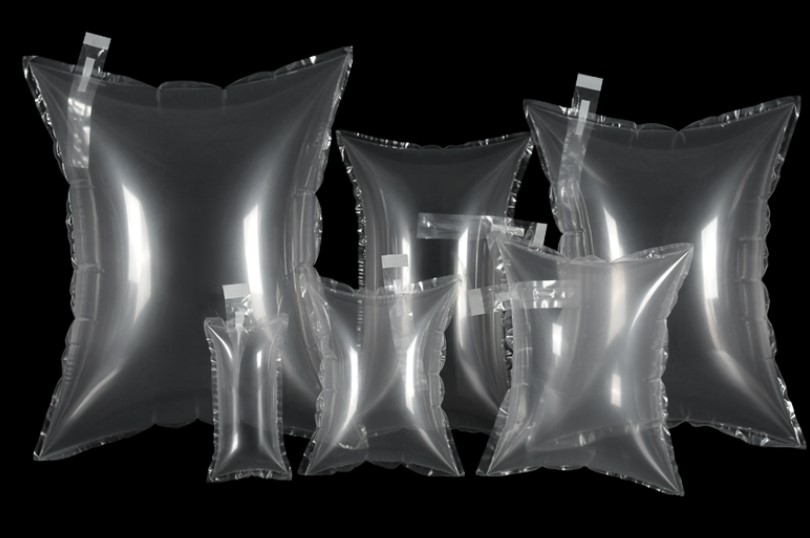

JahooPak Product Details

Strong materials allow the JahooPak Inflate Bag to be inflated on-site, providing superior cushioning and shock absorption to protect breakables while they are being transported.

The film used in the JahooPak Inflate Bag has a surface that can be printed on and is made of double-sided low-density PE and NYLON. This combination provides excellent tensile strength and balance.

|

OEM Available |

|||

|

Standard Material |

PA (PE+NY) |

||

|

Standard Thickness |

60 um |

||

|

Standard Size |

Inflated (mm) |

Deflated (mm) |

Weight (g/PCS) |

|

250x150 |

225x125x90 |

5.3 |

|

|

250x200 |

215x175x110 |

6.4 |

|

|

250x300 |

215x260x140 |

9.3 |

|

|

250x400 |

220x365x160 |

12.2 |

|

|

250x450 |

310x405x200 |

18.3 |

|

|

450x600 |

410x540x270 |

30.5 |

|

JahooPak’s Dunnage Air Bag Application

Stylish Look: Clear, closely matching the product, expertly crafted to improve both the company's reputation and the value of the product.

Superior Shock Absorption and Cushioning: Multiple air cushions are used to suspend and shield the product while distributing and absorbing outside pressure.

Mold Cost Savings: Since customized production is computer-based, there is no longer a need for molds, which leads to quicker turnaround times and cheaper prices.

JahooPak Quality Control

At the end of their useful life, JahooPak Inflate Bag products can be readily separated and recycled based on different materials because they are made entirely of recyclable materials. JahooPak promotes a sustainable approach to product development.

According to SGS testing, the constituent materials of the JahooPak Inflate Bag are non-toxic when burned, devoid of heavy metals, and fall under the seventh category of recyclable goods. The JahooPak Inflate Bag offers strong shock protection and is impermeable, moisture-resistant, and eco-friendly.