Description

PP Woven Air Dunnage Bags represent a cutting-edge solution for securing and safeguarding goods in transit. Constructed from high-quality polypropylene (PP) woven material, these dunnage bags are designed to provide exceptional strength and durability. The bags utilize air inflation to fill void spaces within shipping containers, preventing the movement and potential damage of cargo during transportation. Renowned for their robustness, PP Woven Air Dunnage Bags are well-suited for securing a diverse range of products, ranging from delicate goods to heavy machinery. The woven polypropylene material ensures resistance to tearing and punctures, enhancing the bags’ reliability in demanding shipping environments.

Details

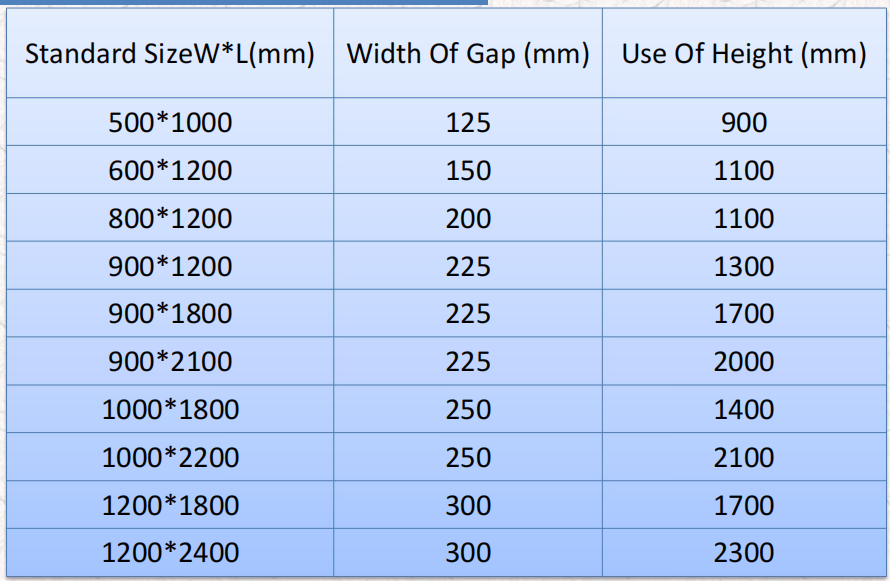

The selection of product length should be based on the height of the cargo packaging, such as palletized items post-loading. It is advisable to position JahooPak cushion airbags above the bottom surface of the loading equipment, such as a container, ensuring they do not exceed the cargo height and remain at least 100 millimeters above the base. JahooPak also accommodates custom orders tailored to specific requirements.

Quality Control

Quality is JahooPak's culture. Every process is strict. And it is traceable. No worries about its quality.

1. Raw Material Inspection Before Production

2. Full Inspection of Inner Film During Production

3. Random Inspection of 3~5% of Dinished Products

4. Burst Test for Each Batch

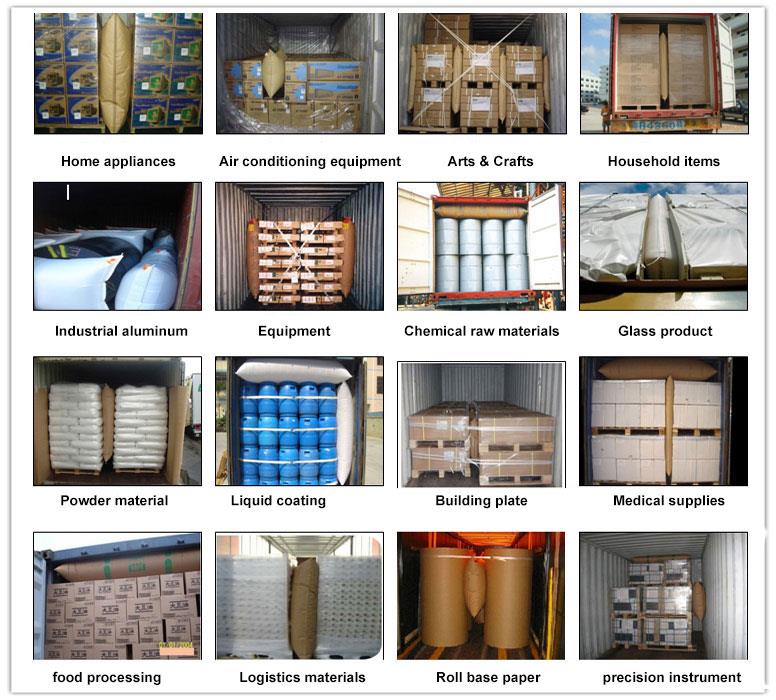

Application

Air bags are widely used in various transportation scenarios that require cushioning protection, such as electronics, handicrafts, precision instruments, etc.

The main usage areas of air bags include:

1.Electronics: Such as displays, TVs, cameras, etc., which are usually very fragile and prone to damage during transportation. Air bags can provide effective cushioning protection.

2.Handicrafts: Such as glassware, ceramics, etc., which are prone to breakage during transportation. Air bags can effectively reduce transportation risks.

3.Precision Instruments: Such as medical equipment, musical instruments, etc., which are highly sensitive to vibrations and impacts. Air bags can provide excellent shockproof and impact protection.

3.Other Fragile Items: Such as cosmetics, fruits, automotive parts, etc., which also need special protection during transportation. Air bags can meet these needs.