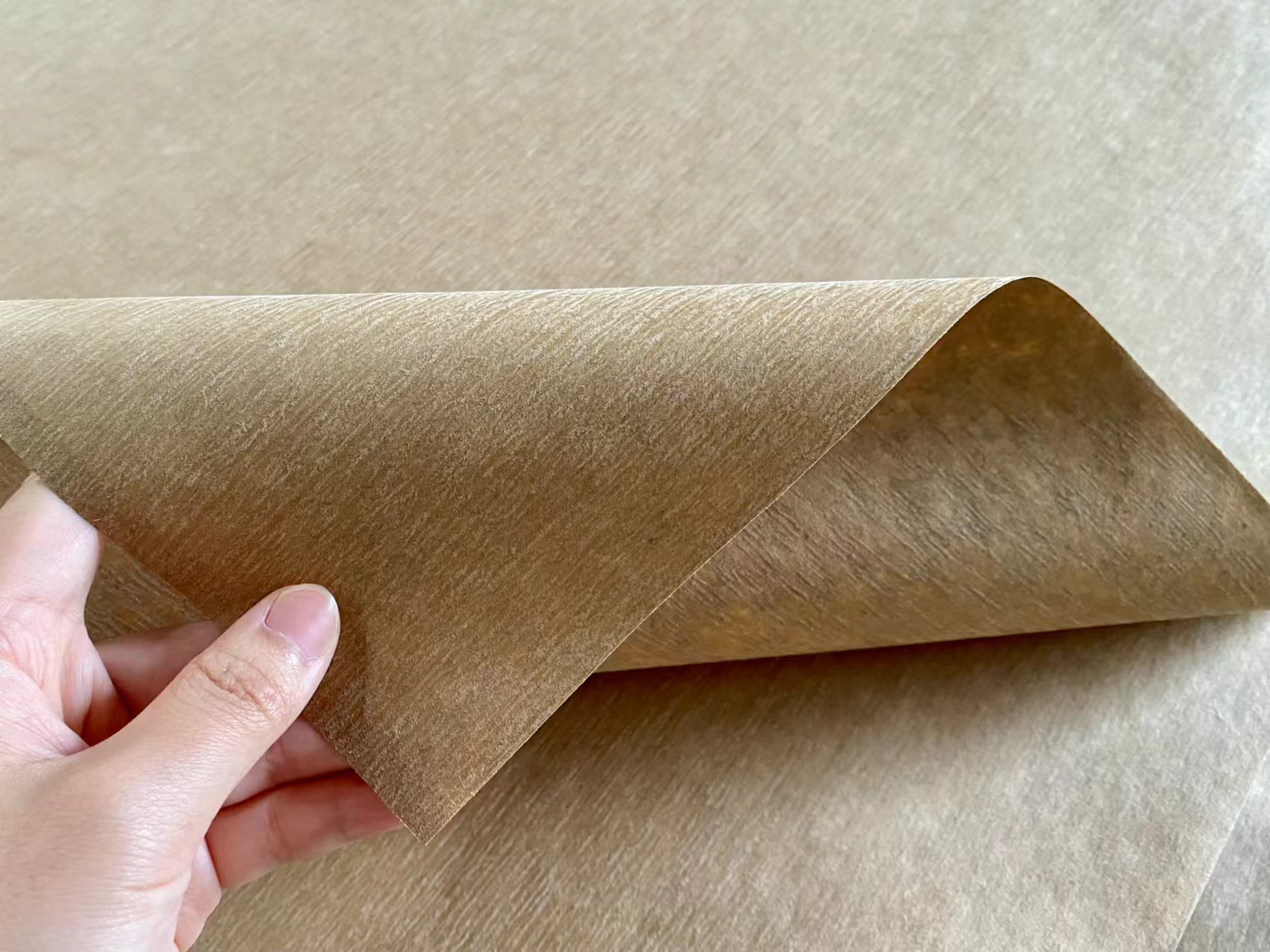

Slip Sheets are manufactured from paperboard, a renewable resource. Slip Sheets are fully recyclable through common wastepaper outlets and have a monetary wastepaper value.Slip Sheets are typically placed between a wooden pallet and the palletized material to prevent palletized products from incurring damage during storage, handling, and shipping.Slip sheets defend bagged and boxed materials against punctures and tears caused by pallet nails and deck boards. They also serve as a moisture-resistant barrier between the ground and your product, preventing mold and mildew. Although slip sheets have the same surface area as a pallet, they take up a lot less space and weigh 80% less. At the same time, they are equally effective due to their load capacity of up to 1,400 kg and their excellent resistance to moisture and tearing. The use of slip sheets offers many logistical advantages.

| 1 | Product name | slip sheet for transportation |

| 2 | Color | Black |

| 3 | Usage | Warehouse & Transportation |

| 4 | Certification | SGS, ISO,etc. |

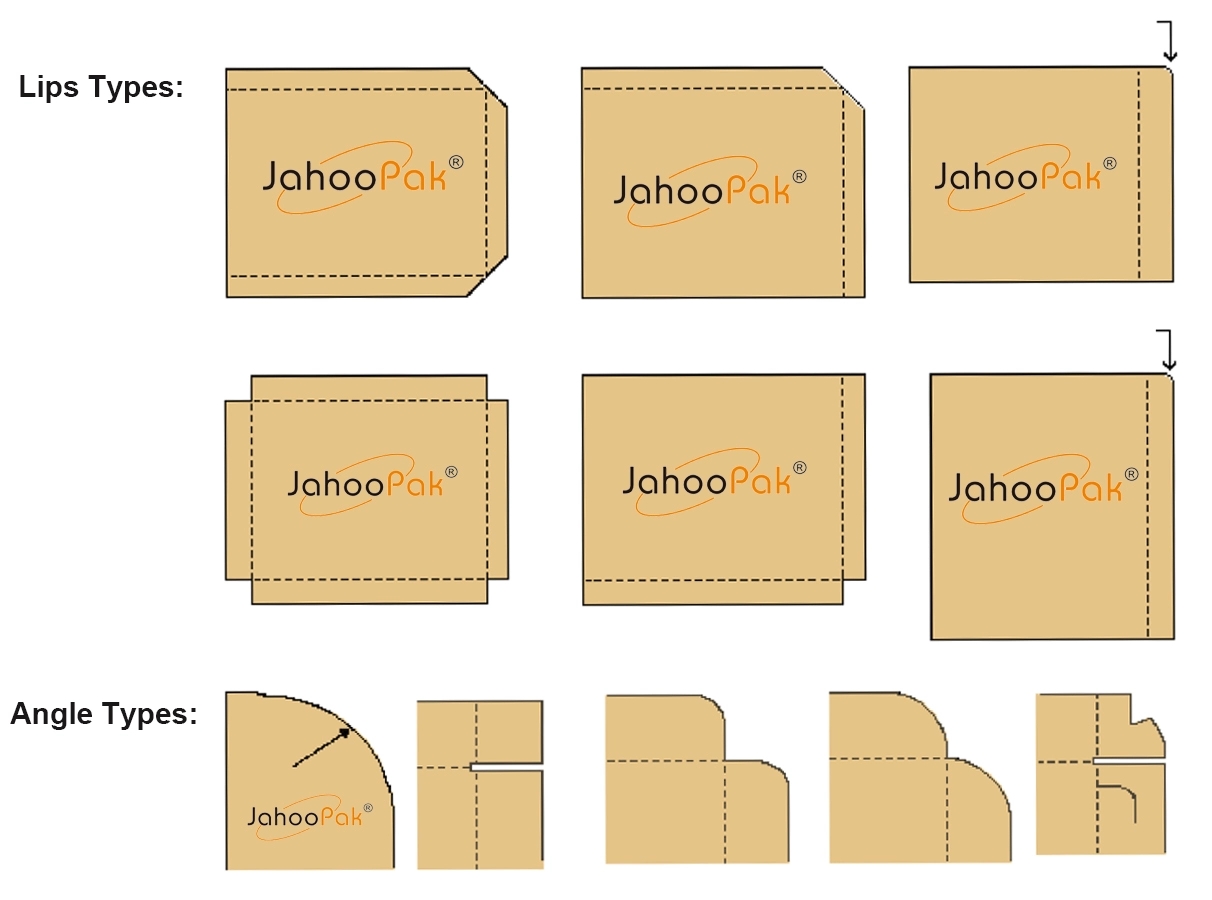

| 5 | Width of lip | Customizable |

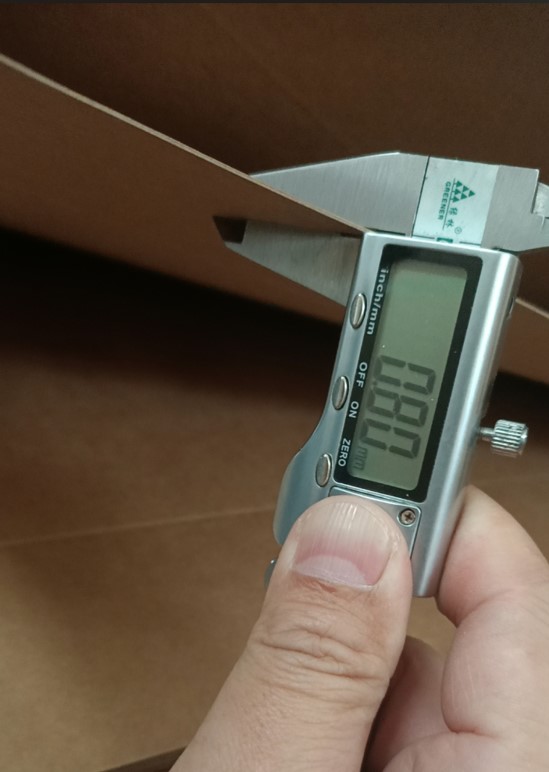

| 6 | Thickness | 0.6~3mm or customized |

| 7 | Loading Weight | Paper slip sheet available for 300kg-1500kg Plastic slip sheet available for 600kg-3500kg |

| 8 | Special handling | Available (moistureproof) |

| 9 | OEM Option | Yes |

| 10 | Drawing picture | Customer offer / our design |

| 11 | Types | One-tab slip sheet; two-tab slip sheet-opposite; two-tab slip sheet-adjacent; three-tab slip sheet; four-tab slip sheet. |

| 12 | Benefits | 1.Reduce the cost of material,freight,labour,repair,storage and disposal |

| 2.Environmentally-friendly, wood-free, hygienic and 100% recyclable | ||

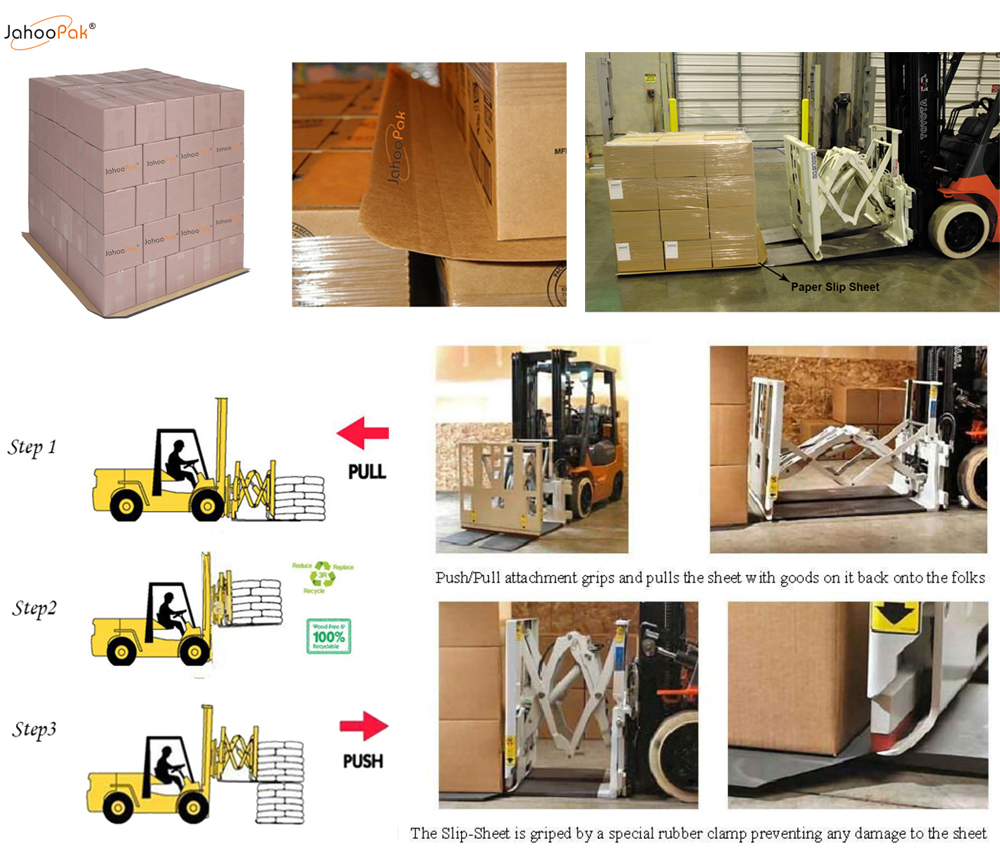

| 3.Compatible with standard forklifts outfitted with push-pull attachments, rollerforks and morden conveyor systems | ||

| 4.Ideal for both domestic and international shippers | ||

| 13 | BTW | For the use of slip sheets all you need is a push/pull-device, which you can get from your nearest fork-lift truck supplier. The device is suitable for any standard fork-lift truck and the investment repays itself faster than you would think. You will get more free container space and save in handling and purchasing costs. |

Product Details

| Thickness (mm) | g/㎡ | loading weight(kgs) | Moisture | Friction coefficient | Material |

| 0.6 | 450 | 0-400 | 13% | 0.55 | Solid Fiber Kraft Paper |

| 0.9 | 750 | 500-800 | 14% | 0.55 | Solid Fiber Kraft Paper |

| 1.2 | 1000 | 1000-1200 | 15% | 0.55 | Solid Fiber Kraft Paper |

| 1.5 | 1250 | 1200-1500 | 16% | 0.55 | Solid Fiber Kraft Paper |

Popular Style

How To Use ?

Application

Quality Control

Packing