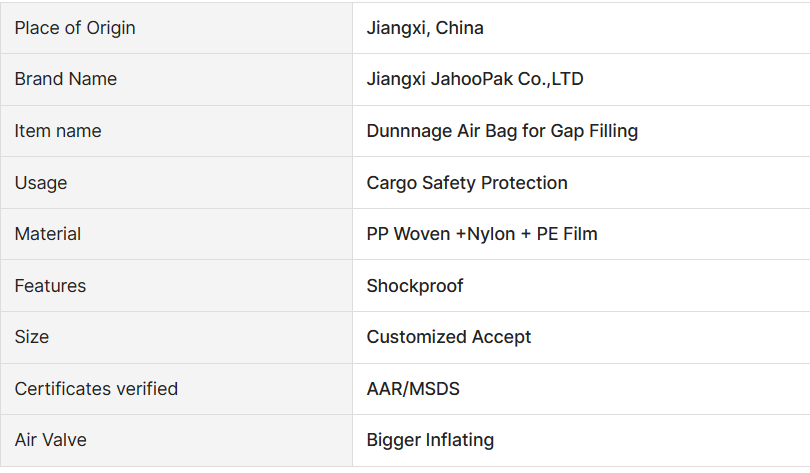

Product Details

How to Choose

Various types of Dunnage Bags can be used to stabilize cargo depending on the type of load and transport.

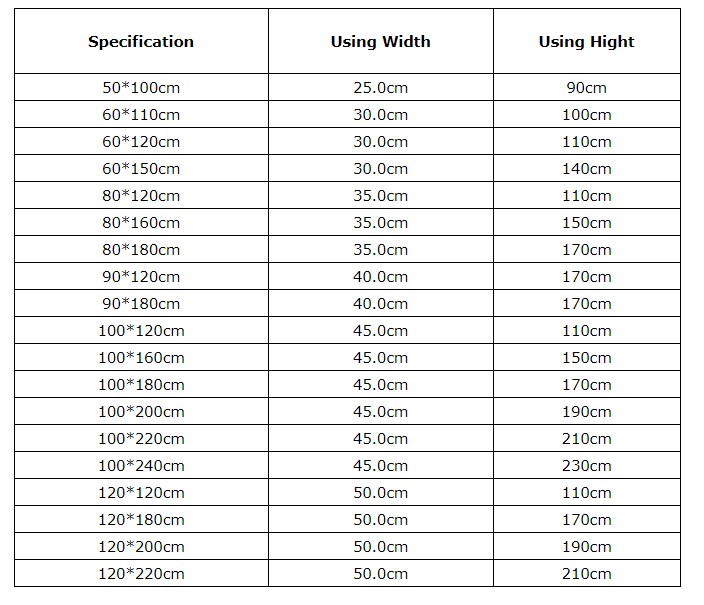

How to correctly select the specifications of the dunnage bags:

1. Measure the height of the pallets;

2. Measure the gap between the goods;

3. Measure the depth of the tray or pallets.

How to Use

Step 1: Load tightly against bulk head. Load each successive row tightly against previous row.

Step 2: Last units placed against side of trailer. Void should not exceed 18 inches. Fill excess void with other appropriate filler material.

Step 3: Always use proper material to protect bags from load face. No sharp edges or points may touch bag. Irregular load surfaces may require rigid buffering material.

Step 4: Attach “Quick Fill” tip by pressing down over the valve. Hold air bag in place until pressure builds up. A single airbag will stabilize the load. Inflate bag until the load is pressed against the sides.

Step 5: Check air pressure once air bag is in place and inflated.

Step 6: Deflate bag by unscrewing cap.

Quality Control

JahooPak's superior polywoven Dunnage Bags have a higher resistance to puncture and moisture and maintain their strength during an entire trip, with independent tests showing them to provide the most secure solution.

1. Raw Material Inspection Before Production

2. Full Inspection of Inner Film During Production

3. Random Inspection of 3~5% of Dinished Products

4. Burst Test for Each Batch