1.Definition of Polyester Fiber Strapping Band

Polyester fiber strapping band, also known as flexible strapping band, is made from multiple strands of high molecular weight polyester fibers. It is used to bind and secure dispersed goods into a single unit, serving the purpose of bundling and stabilization. Unlike PP or PET material strapping bands, polyester fiber strapping bands visibly show the fibers within the band, making it a new environmentally friendly packaging material.

In recent years, with the successful development of new materials and a significant reduction in costs, polyester fiber strapping bands have been widely used in various industries including the steel industry, chemical fiber industry, aluminum ingot industry, paper industry, brickyard industry, screw industry, tobacco industry, electronics industry, textiles, machinery, and woodworking, among others.

After bundling goods with polyester fiber strapping bands, they can retain tension memory for a long time. This not only ensures safe and convenient use but also, due to its flexibility, allows for versatile applications in different fields and environments. Polyester fiber strapping bands are a cost-effective choice; they require only a simple tensioner as a packing tool and can be operated by one person. No power source, compressed air, or strapping tools are needed, making both application and removal quick and easy. They are highly efficient, have excellent penetration and folding properties, and are cost-effective.

2.Advantages of Polyester Fiber Strapping Bands

(1)Polyester fiber strapping bands use M-shaped steel wire buckles for connections, which are scientifically designed. These connections are not only sturdy but also, in a solid state, never loosen or slip off, greatly improving work efficiency and safety during bundling and transportation.

(2)Polyester fiber strapping bands can withstand a tension force of 0.5 to 2.6 tons. They can absorb more impact energy than steel strapping bands, making them suitable for pallet and heavy-duty item bundling. They are less likely to break. After packaging, they provide good tightness, even when the packaged items expand or shrink during long-distance transportation, they maintain good tension.

(3)Polyester fiber strapping bands are lightweight and have no sharp edges like steel straps, which could scratch packaging materials or injure hands. Even when bundled tightly, they do not pose a risk of injury when cut and are more lightweight, flexible, and easier to handle than steel bands.

(4)They can withstand various weather conditions, work normally at 130 degrees Celsius, have good corrosion resistance, and can work in seawater without contaminating products. They can be treated as ordinary industrial waste for simple disposal, contributing to environmental protection.

(5)Polyester fiber strapping bands have a bright and rust-free appearance, providing a neat and sturdy packaging, enhancing product presentation.

(6)Even with large-scale production, the quality remains stable, and a complete range of specifications is available. When used in conjunction with a simple tensioner, they can be operated by a single person, increasing packaging efficiency and reducing packaging costs.

3. How to Use Polyester Fiber Strapping Bands

Tools Required:

(1) M-shaped steel wire buckles, used in conjunction with polyester fiber strapping bands (Specifications: 13/16/19/25/32MM). They are also known as metal wire buckles, steel wire buckles, circular/ring-type buckles. They use high-quality steel wire, are formed by large-scale mechanical stamping, and undergo different surface treatments such as galvanizing or phosphating. They have strong tensile resistance and are a stable method of connection in the industrial packaging industry.

They are widely used in industries such as containers, large machinery, glass, pipe fittings, oil drums, steel, wood, papermaking, and chemicals, offering self-locking and different sizes and strength models.

(2)Manual strapping tools, also known as tensioners, are tools used to tighten and cut strapping bands after bundling or packaging. The function of manual strapping tools is to tighten packaged items, ensuring they are securely bundled during handling and storage, avoiding loose bundling, and ensuring neatness and aesthetics. They use high-quality steel bodies and hardened steel components, are highly durable, cost-effective, lightweight, simple to operate, and provide strong tension.

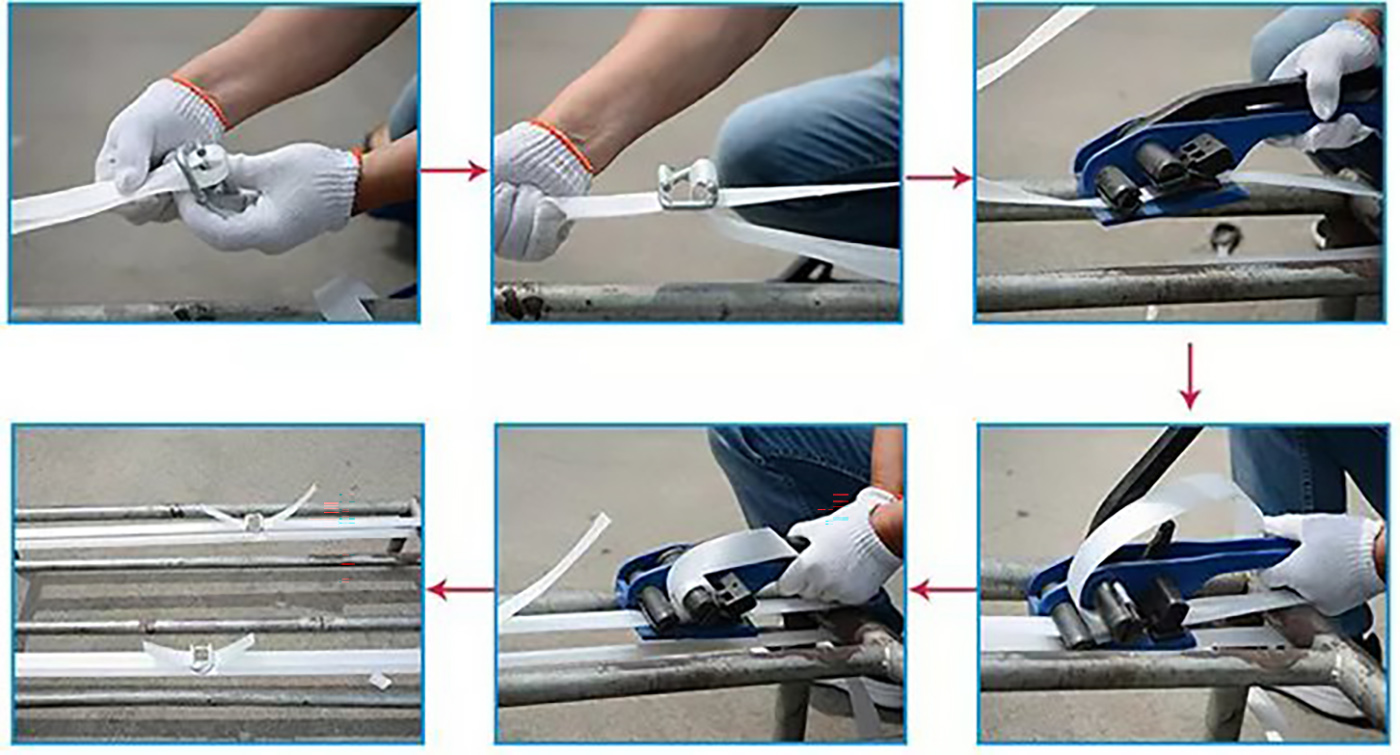

Strapping Method:

(1) Thread the polyester fiber strapping band through the middle of the M-shaped steel wire buckle.

(2) Fold the polyester fiber strapping band and leave approximately 10 centimeters.

(3) Thread one end of the folded polyester fiber strapping band through the adjacent end of the steel wire buckle.

(4) Perform the same operation on the other end, threading the folded polyester fiber strapping band through the middle of the steel wire buckle.

(5) Pass the gap of the polyester fiber strapping band through the steel wire buckle. Finally, pull back to tighten, forming the appearance as shown in the diagram below.

4. Applications of Polyester Fiber Strapping Bands

Polyester fiber strapping bands are suitable for sea, land, and air transportation and are widely used in various industries, including containers, large machinery, military transportation, glass, pipe fittings, oil drums, steel, wood, paper-making, and chemicals, among others.

Timber Bundling

Timber Bundling

Pipe and Steel Bundling

Large Machinery Bundling

Military Transportation Bundling

Post time: Oct-25-2023