1. Definition of Paper Corner Protector

Paper corner protector, also known as edge board, paper edge protector, corner paperboard, edge board, angle paper, or paper angle steel, is made from Kraft paper and cow card paper through a complete set of corner protection equipment, which molds and compresses it. It has smooth and even surfaces at both ends, with no obvious burrs and is mutually perpendicular. Paper corner protectors are used to enhance the edge support and overall packaging strength of goods after stacking.

Paper corner protectors belong to green and environmentally friendly packaging materials. They can replace wood entirely and be 100% recycled, making them an ideal new green packaging material and one of the most popular packaging products worldwide.

The global trend towards low-carbon environmental protection has also reached the packaging industry, advocating the concept of low-carbon packaging. As a protective packaging material for edges, corners, tops, and bottoms, paper corner protectors have opened up a new path for "container-less packaging" for various goods that only need edge and corner protection without the need for overall containment. This not only benefits a wide range of products but also contributes to energy conservation and environmental protection.

2.Advantages of Paper Corner Protectors

(1)Provides sturdy packaging for transportation: The full-wrap structure effectively prevents pressure and moisture, is lightweight, strong, and durable, and provides all-around three-dimensional protection with good compression resistance and cushioning performance. When used in conjunction with strapping or stretch film, it turns loose and fragmented items like paper boxes, sheets, metal pipes, electronic components, and more into a sturdy whole, preventing items from tilting or collapsing.

(2)Edge and corner protection: Paper corner protectors can be used to protect the edges and corners of goods loaded on pallets, reinforcing the pallet and avoiding damage to the corners of the edges during handling, packing, and transportation.

(3)Easy to remove packaging: When removing the packaging, simply cut the strapping or stretch film.

(4)Various sizes available: If paper corner protectors are used only for surface protection without reinforcement, a thickness of 3mm is sufficient, and the dimensions can be determined based on the size of the corner to be protected. To reduce costs, smaller corner protectors can be used to protect corners that may be damaged due to overly tight strapping.

(5)Greater stacking strength: Placing paper corner protectors at the four corners of a paper box enhances its stacking strength, providing cushioning in case of external impact. It also allows paper boxes to be stacked without compressing the items inside.

(6)Recyclable: Paper corner protectors are made by laminating and gluing layers of cardboard, making them recyclable and environmentally friendly. They can also be used in export containers without fumigation, saving costs and finding wide applications.

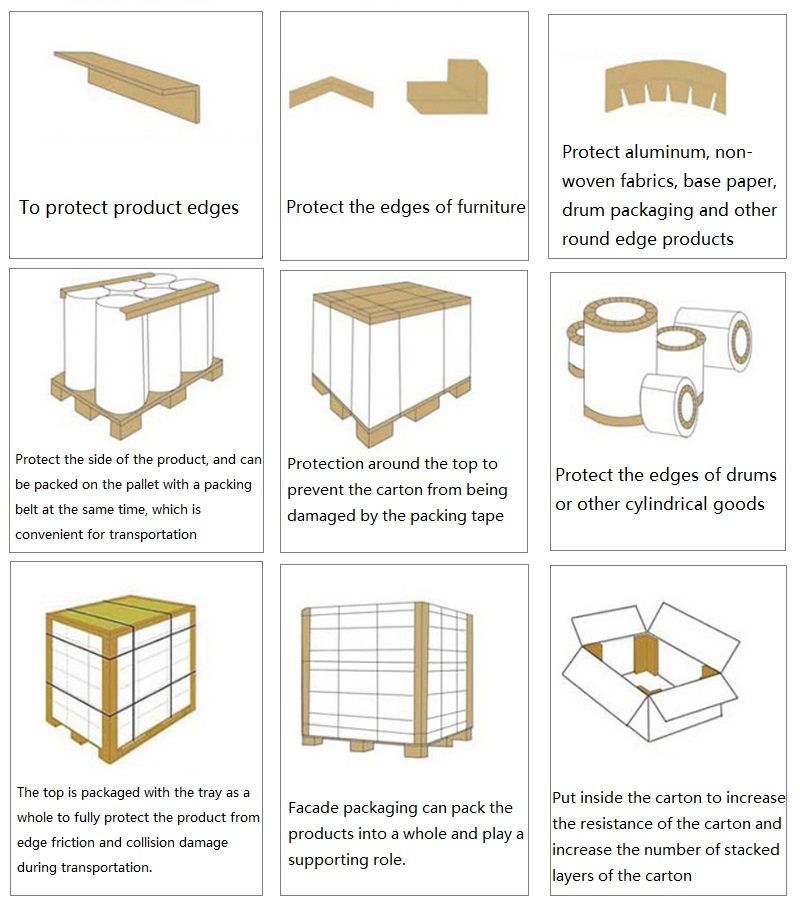

3. Basic Functions of Paper Corner Protectors

Because paper corner protectors can significantly reduce damage to goods during transportation, they are considered an ideal packaging product for improving the external image of products. They have a wide range of uses depending on different transportation methods and environmental conditions.

Preventing external damage: The practicality of paper corner protectors can be compared to wooden boxes. Currently, cargo loss during transportation has become one of the most pressing issues for international businesses. Corner protectors fixed around the goods protect vulnerable edges and corners, reducing cargo loss during transportation.

Creating a packaging unit: When used with strapping, paper corner protectors can be placed on each corner of products packaged as individual units, such as single-piece paper boxes, sheets, metal pipes, etc., creating a strong and stable packaging unit.

Increasing stacking pressure of paper boxes: Paper corner protectors can withstand pressures of up to 1500 kg, making it possible to stack paper boxes together during the transportation of products such as washing machines, microwaves, refrigerators, etc., using short corner protectors at the four corners of the paper boxes. This not only prevents product damage during transportation but also avoids unnecessary damage.

4.Classification of Paper Corner Protectors

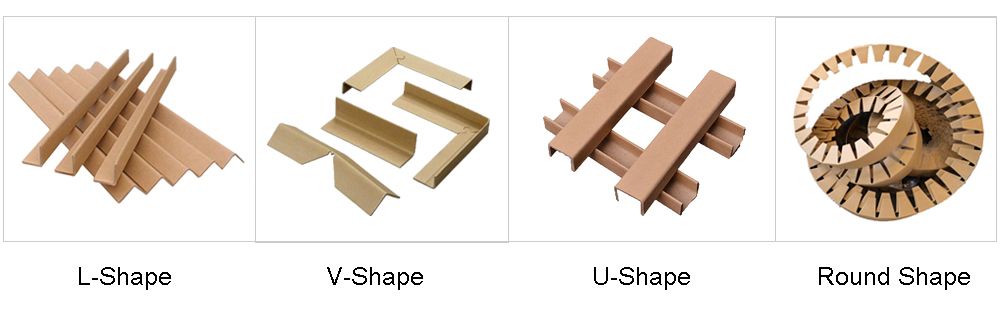

Paper corner protectors are mainly classified as L-Shape, U-Shape, foldable, V-Shape, waterproof, wrap-around, and irregular corner protectors.

V-Shape Paper Corner Protectors: Used for edge and corner protection, and used in conjunction with other types of corner protectors to protect the corners of paper boxes.

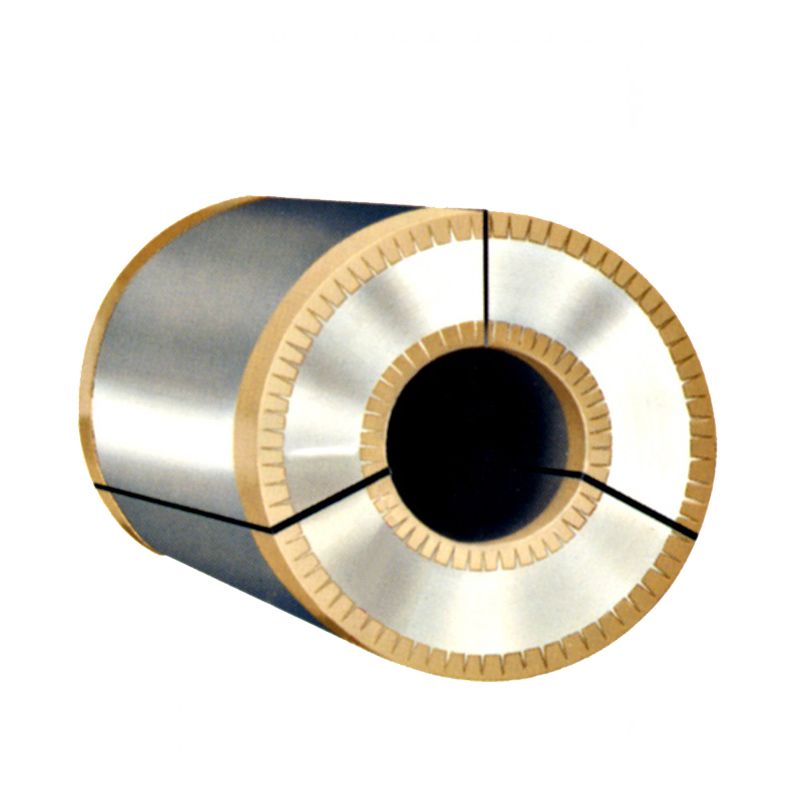

Round Shape Paper Corner Protectors: Used to wrap around both ends of cylindrical products, protecting the packaging of barrel-shaped goods.

L-Shape Paper Corner Protectors: Used to enhance edge support and protection, these are corner protectors for protecting the corners of paper boxes.

5. Applications of Paper Corner Protectors

The main purchasers of paper corner protectors include the construction industry, aluminum manufacturing, steel industry, and other metal industries. Additionally, they are used in brick making, confectionery, frozen foods, daily necessities, household appliances, chemicals, pharmaceuticals, computers, and other high-tech products.

(1)Circular Tubing Packaging

(2)Construction Industry

(3)Stacking Household Appliances

(4)Medical Packaging

Post time: Oct-25-2023