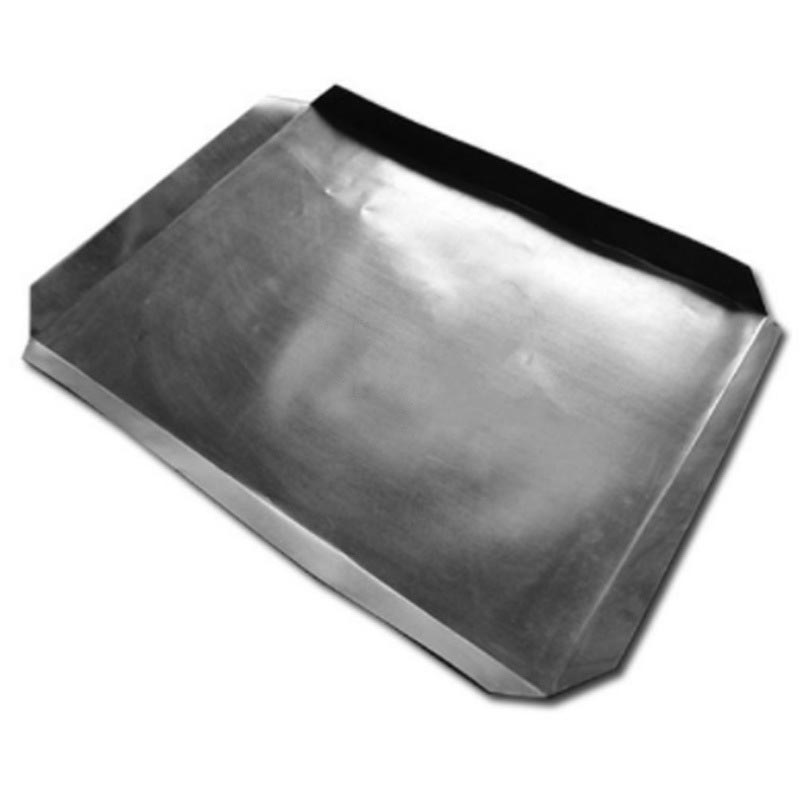

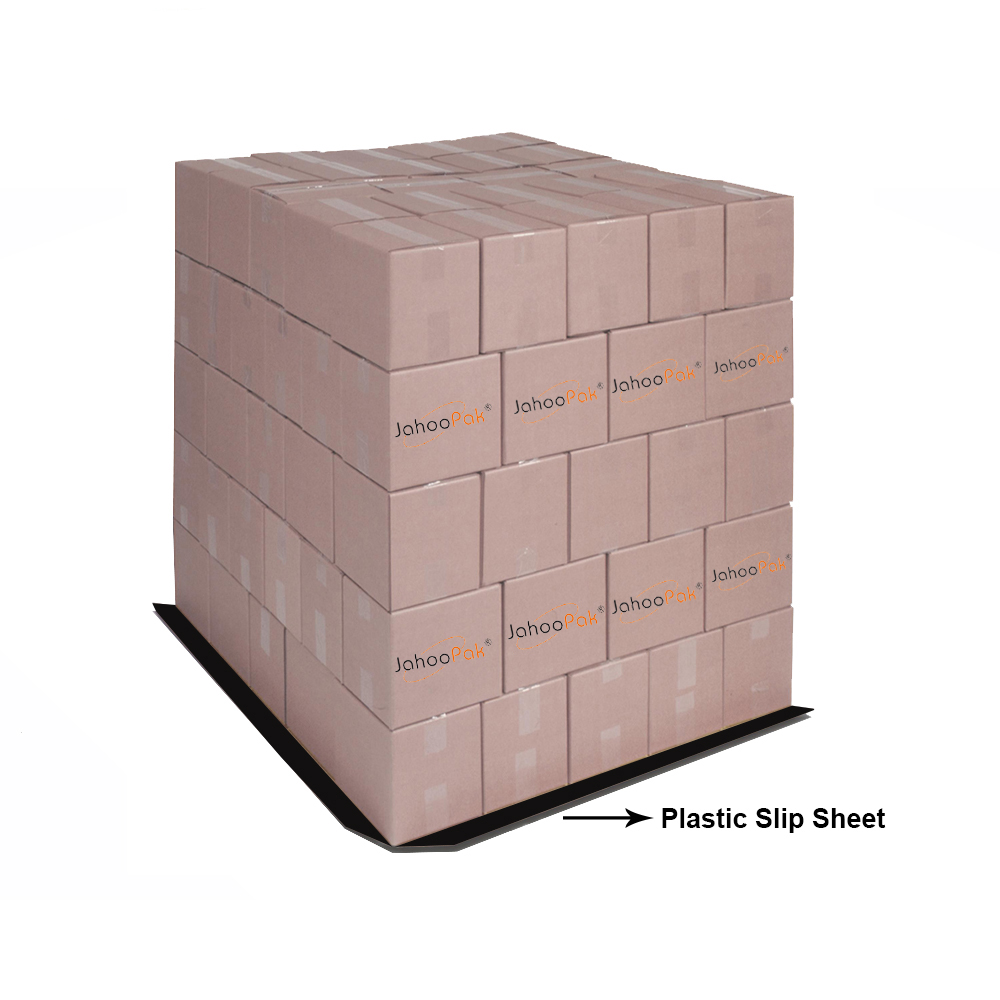

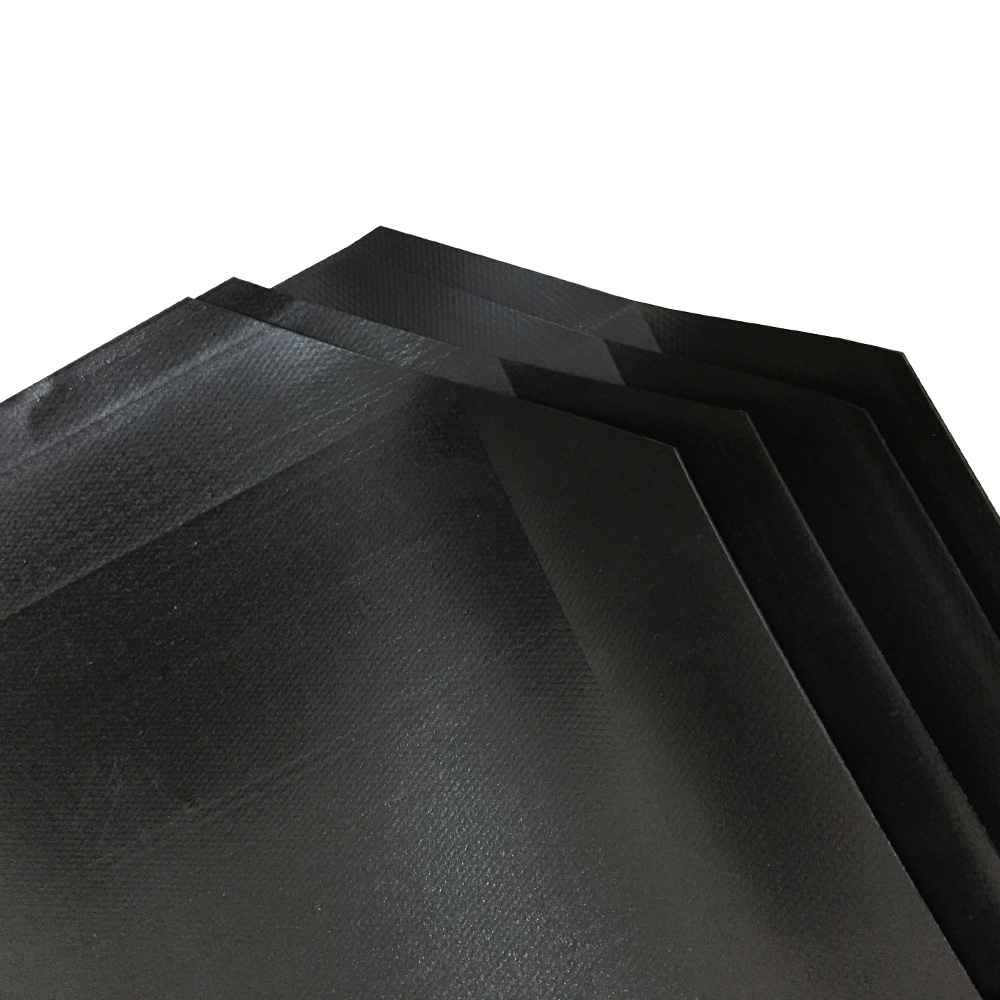

The slim profile of slip sheets is a game-changer in optimizing space utilization during transportation. Unlike the bulkier traditional pallets, slip sheets take up minimal space, enabling the loading of more products onto a single truck or container.The notion of cost-effectiveness is at the core of adopting slip sheets for transportation logistics. The amalgamation of benefits such as reduced transportation costs due to weight reduction, minimized damages ensuring product safety, and optimized space utilization by accommodating more products per shipment, collectively contribute to making slip sheets a highly cost-effective solution.Plastic Slip Sheets are designed for pallet less material handling. It is a flat polyethylene sheet that when placed under an object, allows it to be mobilized. The top surface of the sheet has a greater coefficient of friction (COF) that allows for the product to remain motionless. The bottom surface (slip) has far less COF which allows for the unitized load to move freely. The plastic slip-sheet may be grabbed by one of its sides extra Tab with a device placed on a forklift called a push-pull attachment.

| JahooPak Plastic Slip Sheet | |

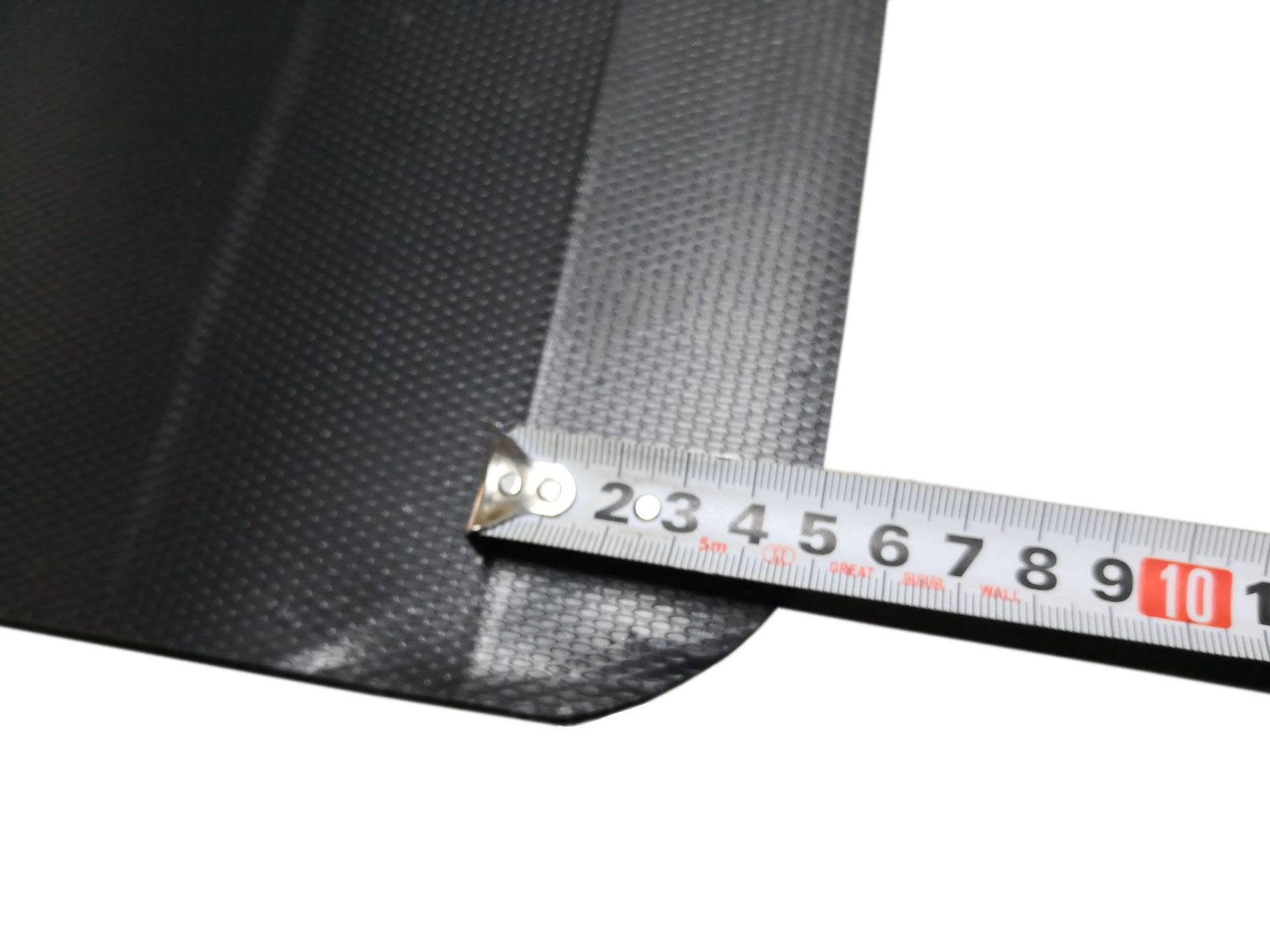

| Slip Sheet Thickness: | 0.6mm -3.0mm |

| Slip Sheet Materials: | HDPE Slip Sheet |

| JahooPak Slip Sheet Size: | As your request |

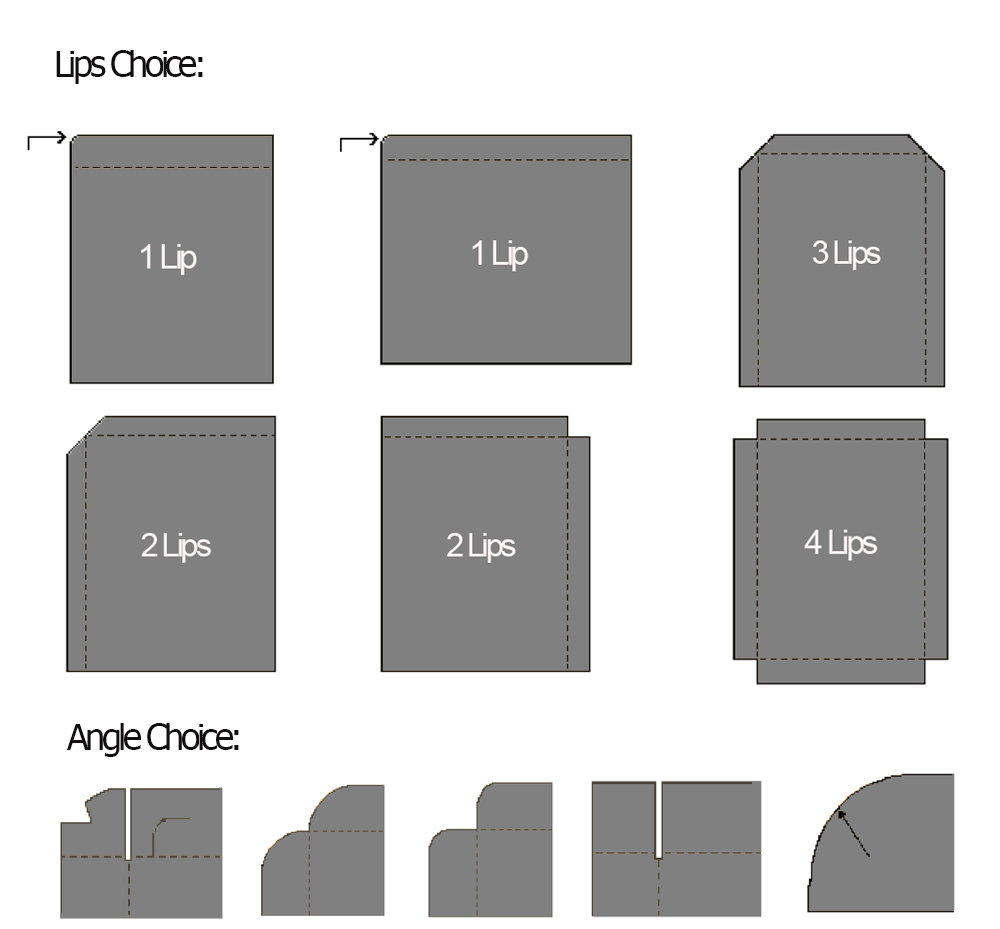

| Slip Sheet Lips/Entry Ways: | 0-4 Lips or as request |

| Slip Sheet Loading Weight: | 500KG-3500KG |

Product Detail

|

Thickness (mm) |

g/㎡ |

loading weight(kgs) |

Friction coefficient |

Material |

|

0.6 |

580 |

0-600

|

0.45 |

Recycle HDPE |

|

0.8 |

750 |

600-800

|

0.45

|

Recycle HDPE

|

|

1.0 |

950 |

800-1100

|

0.45

|

Recycle HDPE |

|

1.2 |

1150 |

1100-1300

|

0.45

|

Recycle HDPE |

Popular Style

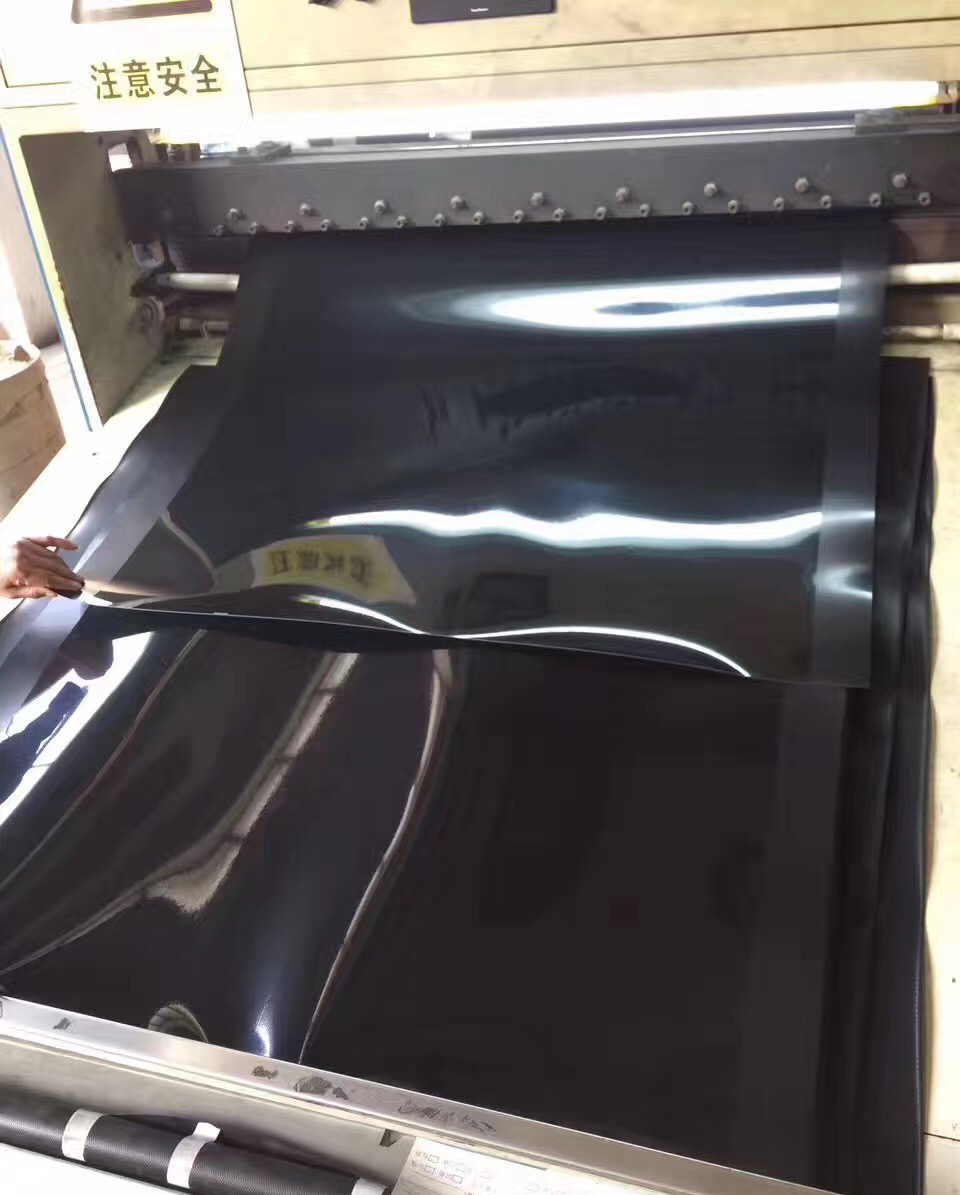

Production Line

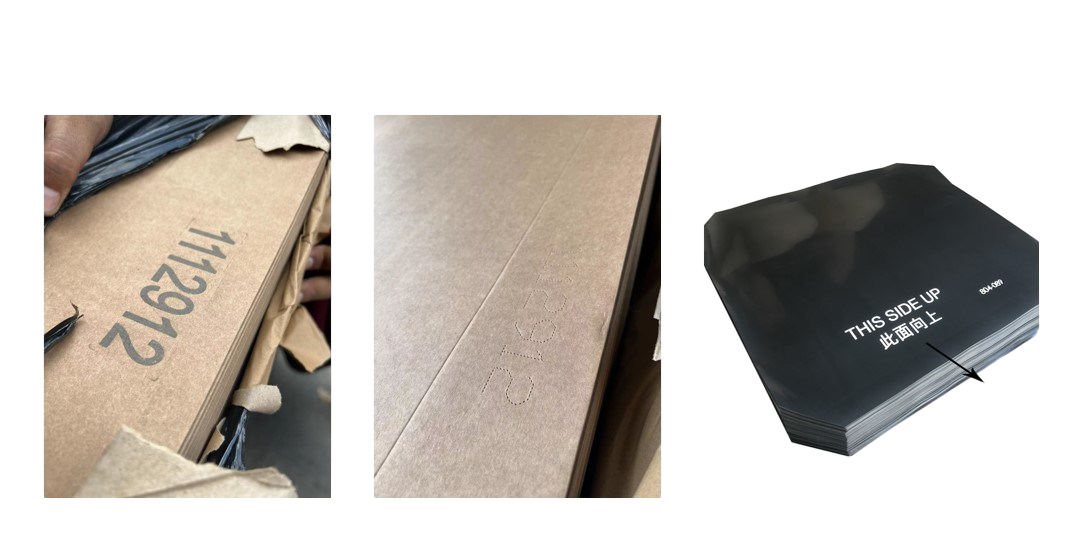

Printing

Packing