Plastic Slip Sheets are designed for pallet-less material handling and provide solutions that improve the economic and environmental impact of transporting products throughout the supply chain.Plastic Slip Sheets are being used worldwide to ship a growing number of products such as: Food and Beverage, Electronics, Chemicals, and Agriculture.Plastic Slip Sheets, the storage and shipping choice of many industries, increase product stabilization and reduce load migration, while meeting unitized load parameters. An economical alternative to other shipping applications, they reduce transportation weight and cost, while allowing for more product in less space.

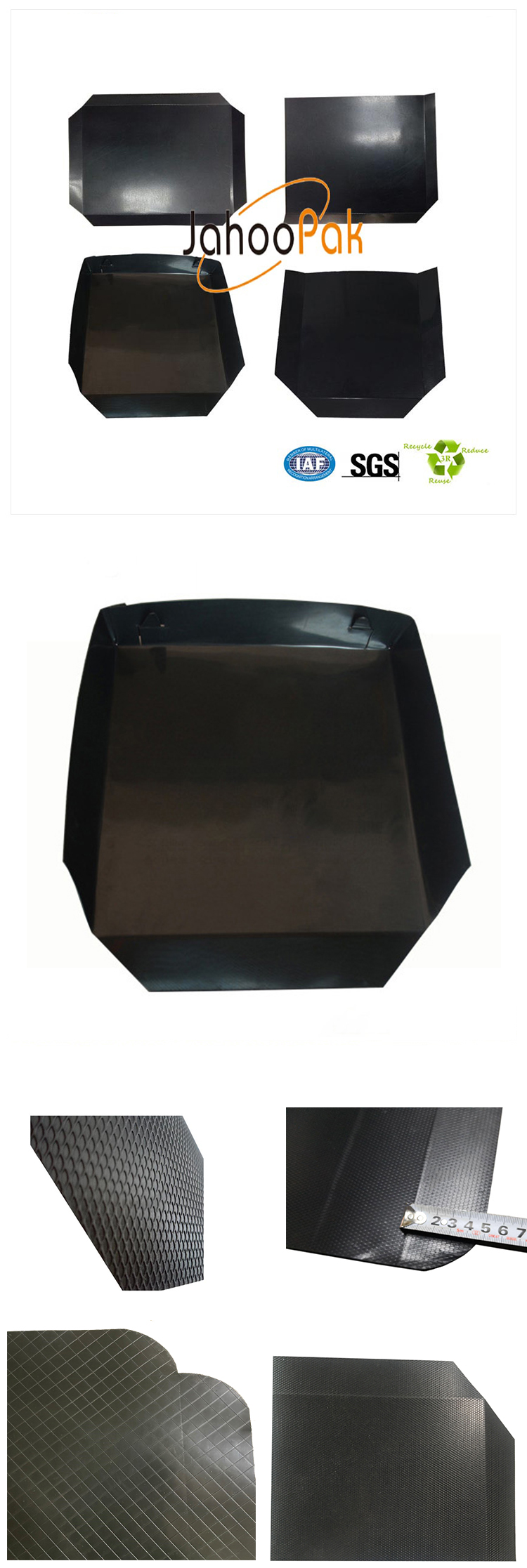

Product Detail

| 1 | Product name | Slip sheet for transportation |

| 2 | Color | Black |

| 3 | Usage | Warehouse & Transportation |

| 4 | Certification | SGS, ISO,etc. |

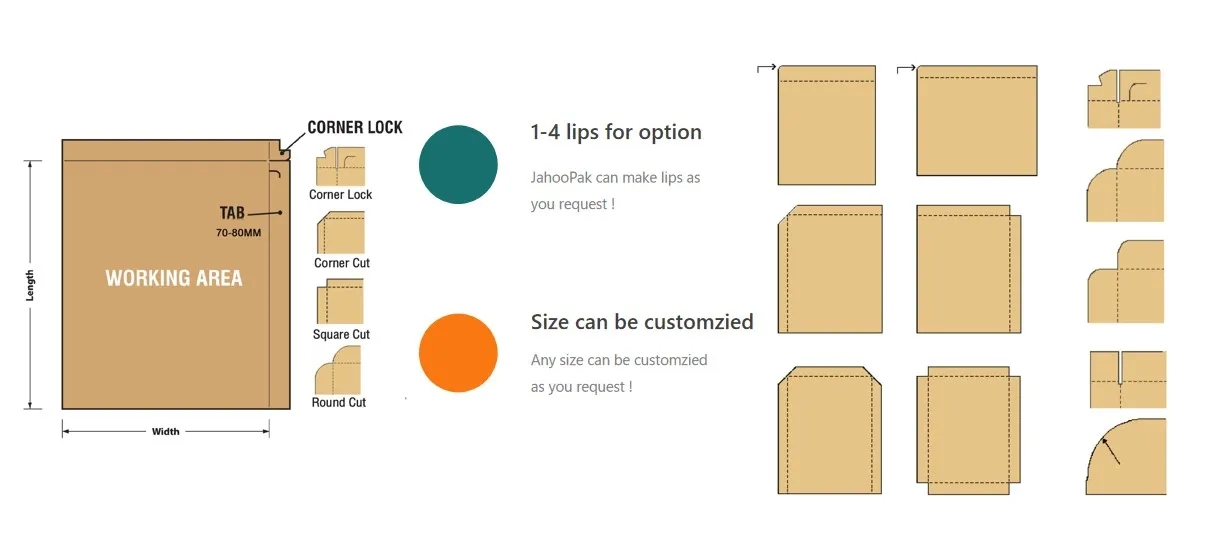

| 5 | Width of lip | Customizable |

| 6 | Thickness | 0.6~3mm or customized |

| 7 | Loading Weight | Paper slip sheet available for 300kg-1500kg Plastic slip sheet available for 600kg-3500kg |

| 8 | Special handling | Available (moistureproof) |

| 9 | OEM Option | Yes |

| 10 | Drawing picture | Customer offer / our design |

| 11 | Types | One-tab slip sheet; two-tab slip sheet-opposite; two-tab slip sheet-adjacent; three-tab slip sheet; four-tab slip sheet. |

| 12 | Benefits | 1.Reduce the cost of material,freight,labour,repair,storage and disposal |

| 2.Environmentally-friendly, wood-free, hygienic and 100% recyclable | ||

| 3.Compatible with standard forklifts outfitted with push-pull attachments, rollerforks and morden conveyor systems | ||

| 4.Ideal for both domestic and international shippers | ||

| 13 | BTW | For the use of slip sheets all you need is a push/pull-device, which you can get from your nearest fork-lift truck supplier. The device is suitable for any standard fork-lift truck and the investment repays itself faster than you would think. You will get more free container space and save in handling and purchasing costs. |

Product Specification

| Thickness (mm) | g/㎡ | loading weight(kgs) | Moisture | Friction coefficient | Material |

| 0.6 | 580 | 0-600

|

2% | 0.45 | Recycle HDPE |

| 0.8 | 750 | 600-800

|

2%

|

0.45

|

Recycle HDPE

|

| 1.0 | 950 | 800-1100

|

2%

|

0.45

|

Recycle HDPE |

| 1.2 | 1150 | 1100-1300

|

2%

|

0.45

|

Recycle HDPE |

Product Cutting

Popular Style

Application

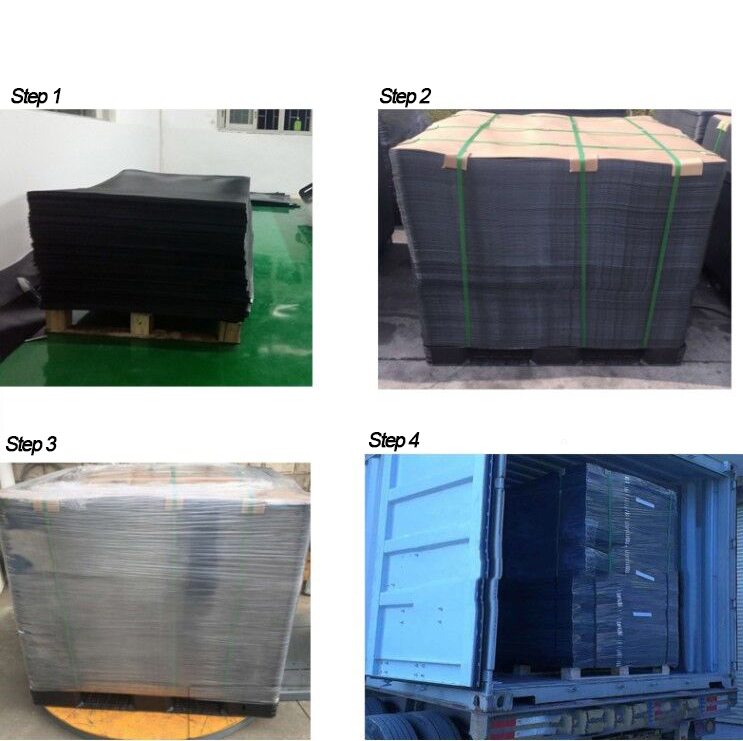

Packing

Company Profile