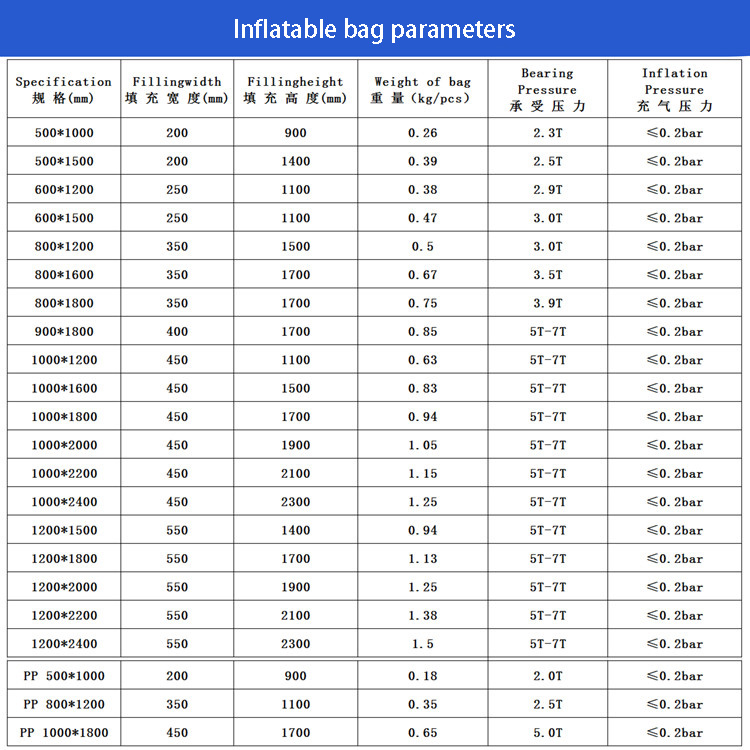

Features & Benefits:

- Available in several different types and sizes, depending on the products and mode of transportation.

- Have a very high strength due to complete unique choice of materials and composition.

- Made from environmentally friendly materials. Reusable and recyclable.

- Meet the European regulations regarding the content of heavy metals.

Air Valve

Our dunnage air bags are equipped with a patented valve, which allows fast inflation and deflation. When used with our inflator the time for inflation and deflation is significantly reduced.

Loading Tips:

Clean the floor of the trailer and inspect floors, walls and roof for nails or holes before loading. Remove or hammer down nails or other sharps.

Load skids tight from front to back and from side to side. Tight means touching.

Use side shifters on the fork lift to position freight in firm contact with the sidewall or other skid of freight. Also to control void size.

Alternate the void from side to side to balance the load.

Put tallest freight in the nose at the first load position and bag it.

Put the most fragile freight towards the nose for the softest ride.

Use additional bags when necessary to stabilize unsteady skids.

Always bag when dropping from two high to one high loading.

Always bag the final load position.

Techniques for Easy Installation:

Insert inflation tool into valve.

Visually locate the best void to install the bag while walking in.

Give the bag a small puff of air to give it some stiffness and bulk.

Insert bag all the way into the void before inflating. Valve should be at top if possible. One hand should be on the inflation tool and one hand should be positioning the bag.

If bagging a high load position, you may tape the bag to the top of one unit before loading the other side.

When inflating, watch the freight not the bag. 1 – 3 lbs psi recommended. When the freight is tight against the wall, disengage the inflator. Don’t worry, the bag will not over-inflate! Installation is complete when the inflator blows back.

After inflation, screw on over-cap.

Deflation (Patented walk-away feature):

Remove over-cap, push valve in and twist one quarter turn clockwise.

You can walk-away while bag deflates!

Remove bag, inspect for damage and set aside for reuse.