Air Dunnage Bag is an innovative and easy transporation protection tools, with PP and PE made of kraft paper coated, tough and firm, inside the bag is mainly of three layers PE made arch crowded membrane, One –way non- return valve inflatable or put gas fack with swift, airtight firm, effecitively prevent in trucks, container or railway transport goods collide each other. If air dunnage bags fully filling the space between the goods, goods produced by shaking supported the weight, absorb shock, protect the goods from damage in transit, than anyother support filling protect content effect is better, than with foam plastic etc traditional filling way more environmentally friendly.

Container air bag typically consists of three main parts: the outer layer, inner layer, and valve. The outer layer is made of durable and puncture-resistant material, such as kraft paper, woven polypropylene, or a combination of both. The inner layer is typically made of a polymer film that can withstand high pressure and prevent air leakage. The valve, which is located on one end of the air bag, allows for inflation and deflation of the bag.

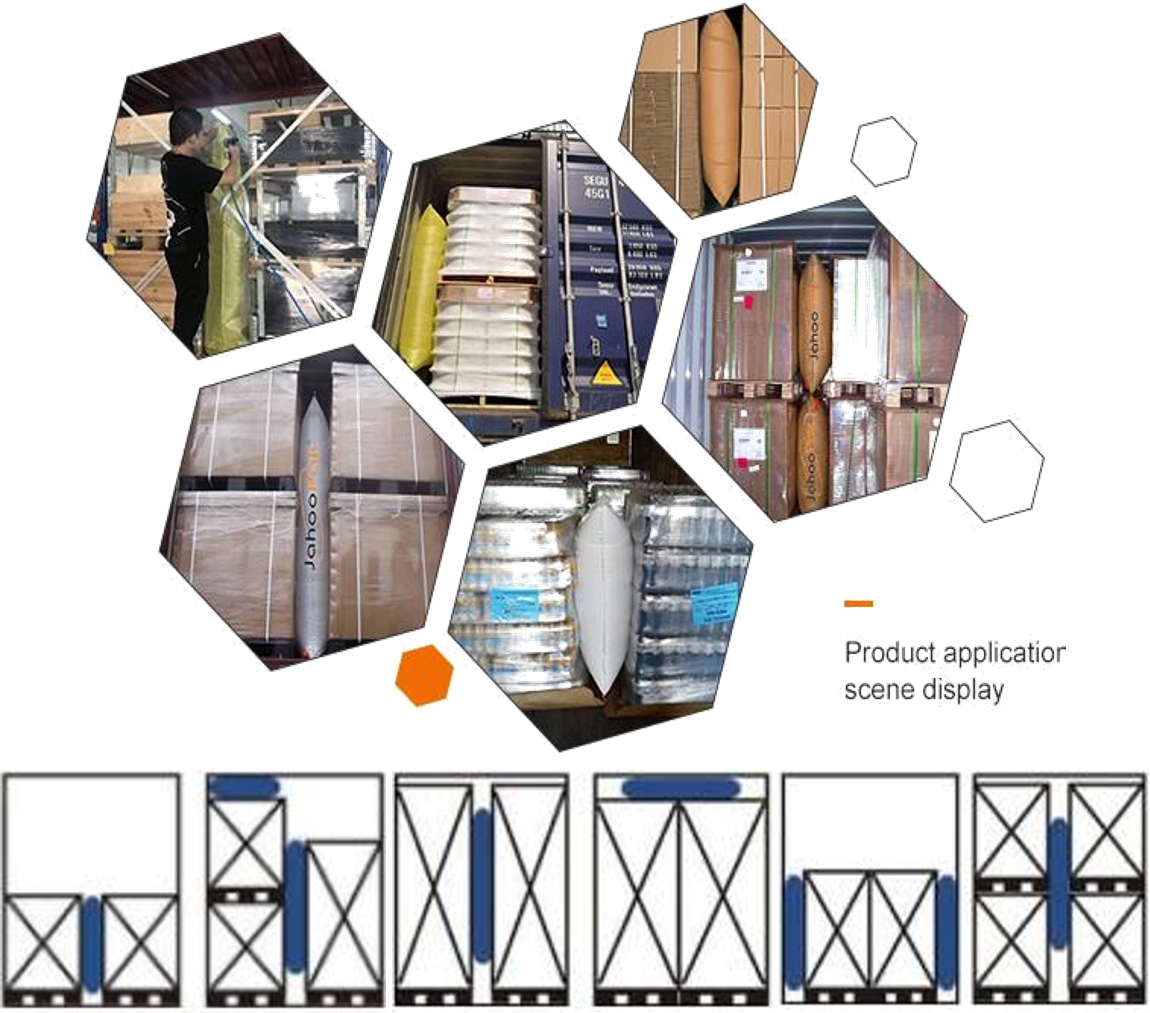

Once the air dunnage bag is properly positioned within the container, it is inflated with compressed air using a specialized tool, filling the void space and providing support and stability to the cargo during transportation. Once the shipment has arrived at its destination, the valve can be easily opened to release the air and deflate the bag, making it easy to remove and store for future use.